| PLANTS, EVAPORATORS AND AUTOMATION PROCESSES |

|

| RETORT AND CHAMBER FURNACES FOR CONTROLLED ATMOSPHERE | ||

| ||

ROHDE furnaces are designed according to customer needs. Energy consumption is very low and heat-up and cool-down times are very short due to good insulation and extremely low heat storage. The temperature constancy values inside the retort are optimal.

| ||

| BRINE – EVAPORATOR SYSTEM TYPE VH FOR AS-SALTS | |

| |

|

There are different ways to retrieve the quenching salt, which is recovered by ROHDE-Evaporator-Systems. Therefore, the individual circumstances and preferences of the customers have to be considered. The following possibilities are available: FEATURES OF THE EVAPORATOR - SYSTEM FURTHER OPTIONAL ACCESSORIES | |

| PROCESS VISUALIZATION AND CONTROL | |

| |

|

We utilise all common program controllers for the automated and reproducible run of different processes.

We are not bound to any defined product. Depending on the existing infrastructure and the already introduced systems we can fulfil your individual demands

State-of-the-art controllers naturally enable us to carry out a remote maintenance at your equipment.

We will pleased to send you a quote to update and revise controllers at your existing equipment according to state-of-the-art technology: | |

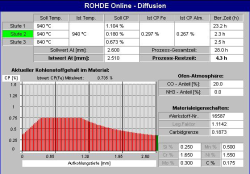

| ROHDE ONLINE DIFFUSION SYSTEMS FOR GAS-NITRIDING AND NITRO-CARBURISING | |

| |

|

The software we have developed for online diffusion can be utilised for standard gas carburising processes as well as for carbo- nitriding processes. For any carburising depths between 0,2 – 10 mm the program initially calculates on the basis of the material a proposition for a treatment program and predicts the duration of the complete treatment. The program then suggests a multistage process whereas in the first stage the C-level is calculated automatically depending on the carbon activity (carburising near smoke limitation). In the balancing stage of the diffusion the C-level is automatically adjusted in order to achieve the desired C-concentration in the surface. | |

| ROHDE CONTROL SYSTEM FOR GAS-NITRIDING AND NITRO-CARBURISING PROCESSES | |

| |

|

The core of the system is a sensor developed to supervise the ammonia decomposition due to a thermodinamic unbalance. The system enables us to achieve reproducibly the requested nitriding depths and at the same time to distinguish between gamma and epsilon-layers. Furthermore our control system is able to control nitriding depth and compound layer. | |

Metalconsulting S.a.s. di Paolo Fossati & C. - V.le Susani, 52 - 20844 Triuggio (MB)

tel: 0362-918394 - fax: 0362-978328 - P. Iva 00782180962, info

tel: 0362-918394 - fax: 0362-978328 - P. Iva 00782180962, info